Why We Exist?

BRD Lucchini was established to bridge the gap between technical engineering and commercial product development. We saw that many engineering firms focus solely on specific components without considering the broader manufacturing, regulatory, and commercial risks.

Our founders recognised that successful products need engineers who understand the complete picture – identifying and mitigating risks early while developing solutions that can be efficiently manufactured, meet compliance standards, and deliver measurable value to end users.

How We Think

BRD Systems Approach

We approach every project as an integrated system rather than isolated components. By considering how mechanical, electronic, software, and compliance requirements interact, we identify issues and dependencies that others miss. This systems thinking helps eliminate costly rework and integration problems later in development.

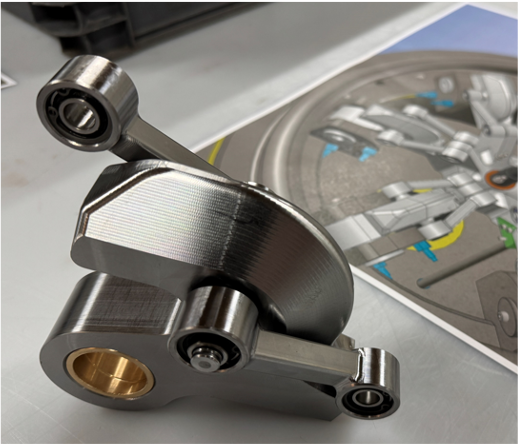

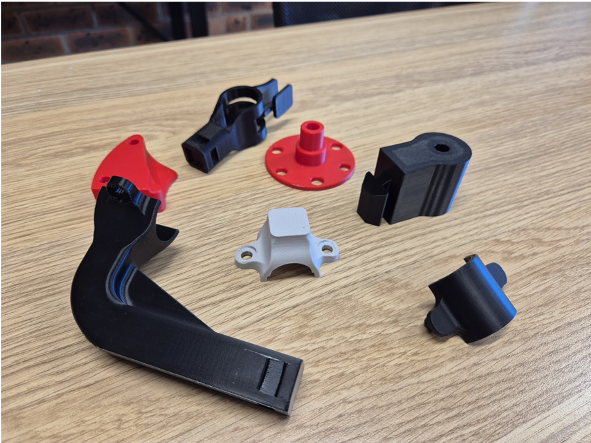

Design for Manufacture

Technical elegance means little if a product can't be efficiently manufactured. We evaluate production methods, material selections, and assembly processes from concept stage, ensuring designs transition smoothly from prototype to volume production with minimal changes. This approach reduces time to market and capital investment.

Cross-Functional Integration

Our experience across mechanical engineering, mechatronics, and compliance enables us to bridge traditional discipline boundaries. This integration produces more cohesive solutions where mechanical systems, electronic controls, and regulatory requirements work together seamlessly rather than being patched together at the end.

Product Development

BRD Lucchini Engineering was founded by engineers with extensive real-world experience across medical device development, industrial automation, and mechanical systems.

Based in Wollongong, our leadership team has delivered commercial products for the medical industry mining operations, energy providers, and agricultural equipment suppliers to the global market and associated regulatory requirements. This work has built our expertise in mechanical design, mechatronic systems, and manufacturing processes across diverse industry requirements.

Industries We Work In

Medical Devices

ISO13485-informed design and documentation for Medical devices, including surgical instruments, RF equipment, and implantable devices. We help navigate the path from concept to regulatory submission.

Mining & Industrial

Robust mechanical systems, equipment upgrades, and automation solutions designed for harsh environments and continuous operation. Our work includes pneumatic and hydraulic design processing equipment, and safety mechanisms.

Agriculture

AgricultureDevelopment of robust mechanical solutions to provide Australian farmers process improvements through safer and more efficient products used in day-to-day operations.

Energy

Precision components and control systems for energy generation and distribution, with emphasis on reliability, safety compliance, and long-term performance. We work with both traditional and renewable energy providers.

Product Startups

Targeted engineering support for hardware startups, focusing on design for manufacture, cost optimisation, and technical documentation that supports successful commercialisation and investor confidence.

Our Approach

Our Core Values

Engineering Transparency

We document decisions and communicate clearly, ensuring clients understand the rationale behind our approach and recommendations.

Combined Experience

Practical Solutions

We focus on designs that work in the real world, considering manufacturing constraints, maintenance needs, and operational conditions.

Cross-Functional Integration

We break down traditional engineering silos, bringing mechanical, electronic, software, and compliance considerations together from the start.

Client Collaboration

We work as an extension of your team, integrating your expertise and requirements into every stage of the development process.